Rope clamshell grab

Advantage of mechanical grab

Clamshell Mechanical Grab is the perfect solution for efficient and convenient material handling. This innovative and reliable machinery is designed to optimize productivity and reduce manual labor in various industries including construction, mining and logistics. With their superior features and superior performance, clamshell mechanical grabs are sure to revolutionize the way materials are handled.

Clamshell mechanical grapples offer a range of advantages that set them apart from traditional material handling equipment. First, its unique clamshell design enables precise, controlled gripping, ensuring safe and efficient transfer of materials. This grapple is designed with high quality components for durability and longevity even under heavy duty operations. The significant advantage of the clamshell mechanical grab is its user-friendly operation. I This user-friendly interface shortens the learning curve and promotes efficient operation, enabling operators to achieve higher levels of productivity in less time.

In addition, the clamshell mechanical grab is designed with safety in mind. It is equipped with reinforced hooks and shackles for extra safety during material handling. The grapple's sturdy construction and reliable grabbing mechanism ensure that materials are securely held during transport, minimizing the chance of accidents or spills.

Why choose GBM as your grab supplier?

1.As a leading manufacturer of 5000 square feet dedicated, licensed and certificated staff.

2.Mechanical and machinery design, structural design and analysis dynamic modeling and seismic, failure modes and effects analysis Auto CAD, 3DMax, Math CAD, Solid Works, ANSYS and SAP2000 Advanced.

3.All Main parts using reliable original imported brand.

4.GBM provide the SGS, CCS, BV, CE, ABS, ISO9000:2008, ISO14001:2004, OHSAS and etc certifications, also accept third party inspection, such asSGS Factory test etc.

All the product design drawing and calculation is reasonable and meet the international standard, all the productions drawing and calculation will be audit before production.

5.The welding meet the international standards, and no damage detection reports are required.

6.On the testing the actual lifting capacity is 1.25 times than the rated lifting capacity and will issued exactly testing report according to the technical agreements

GBM grab experience in career

3 unit 17CBM mechanical grab

Project located in Netherlands

2 unit ship loader grab

Project located in Vietnam

8 unit 14CBM two rope grab

Project located in Thailand

2 unit 12CBM two rope grab

Project located in Morocco

20 unit 6-12CBM remote control grab

Project located in UAE

7 unit 6CBM two rope grab

Project located in Ghana

2 unit 15CBM mechanical grab

Project located in Japan

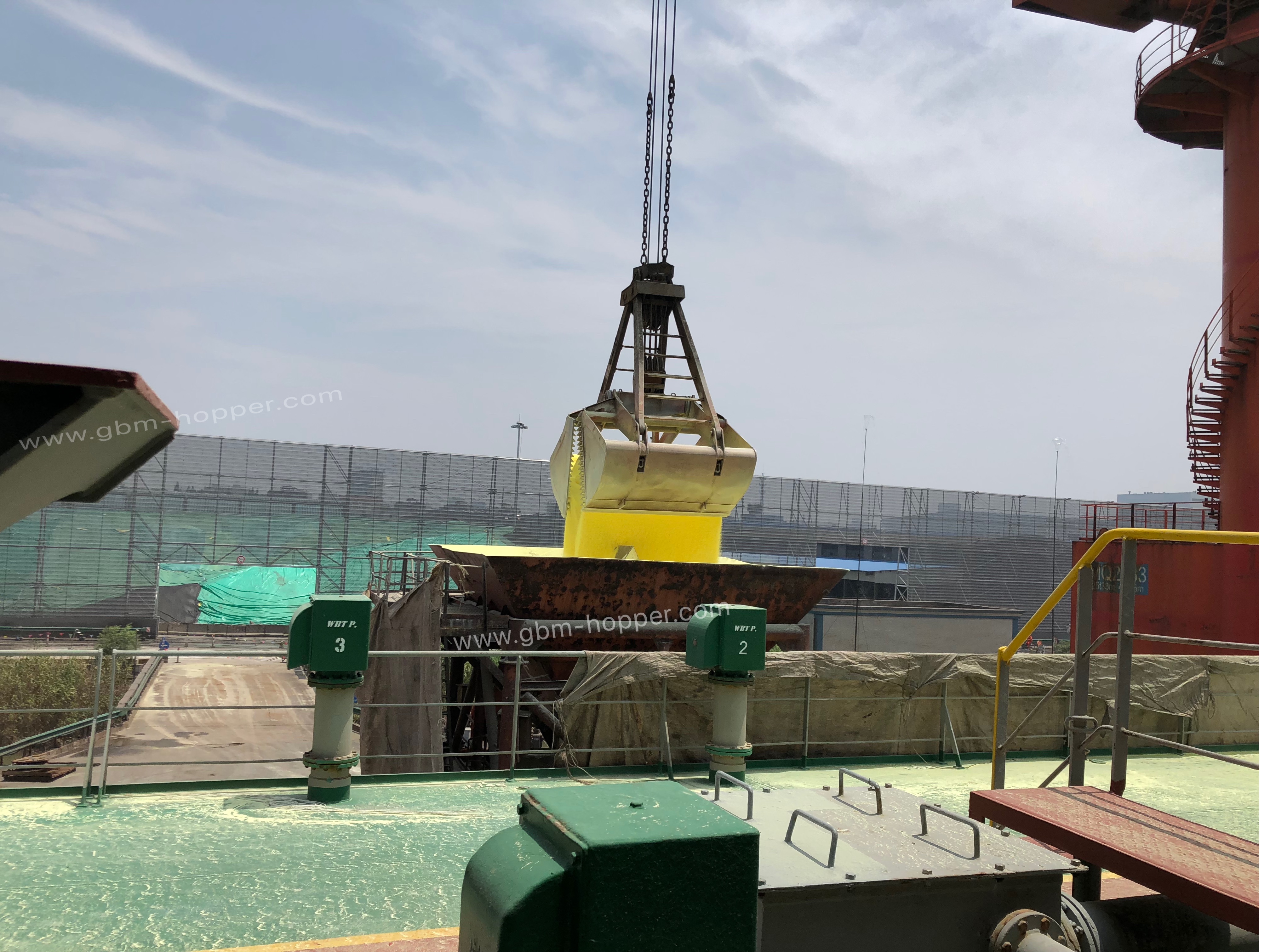

5 unit 7CBM four rope grab

Project located in Hongkong

1 unit 12CBM four rope grab

Project located in China

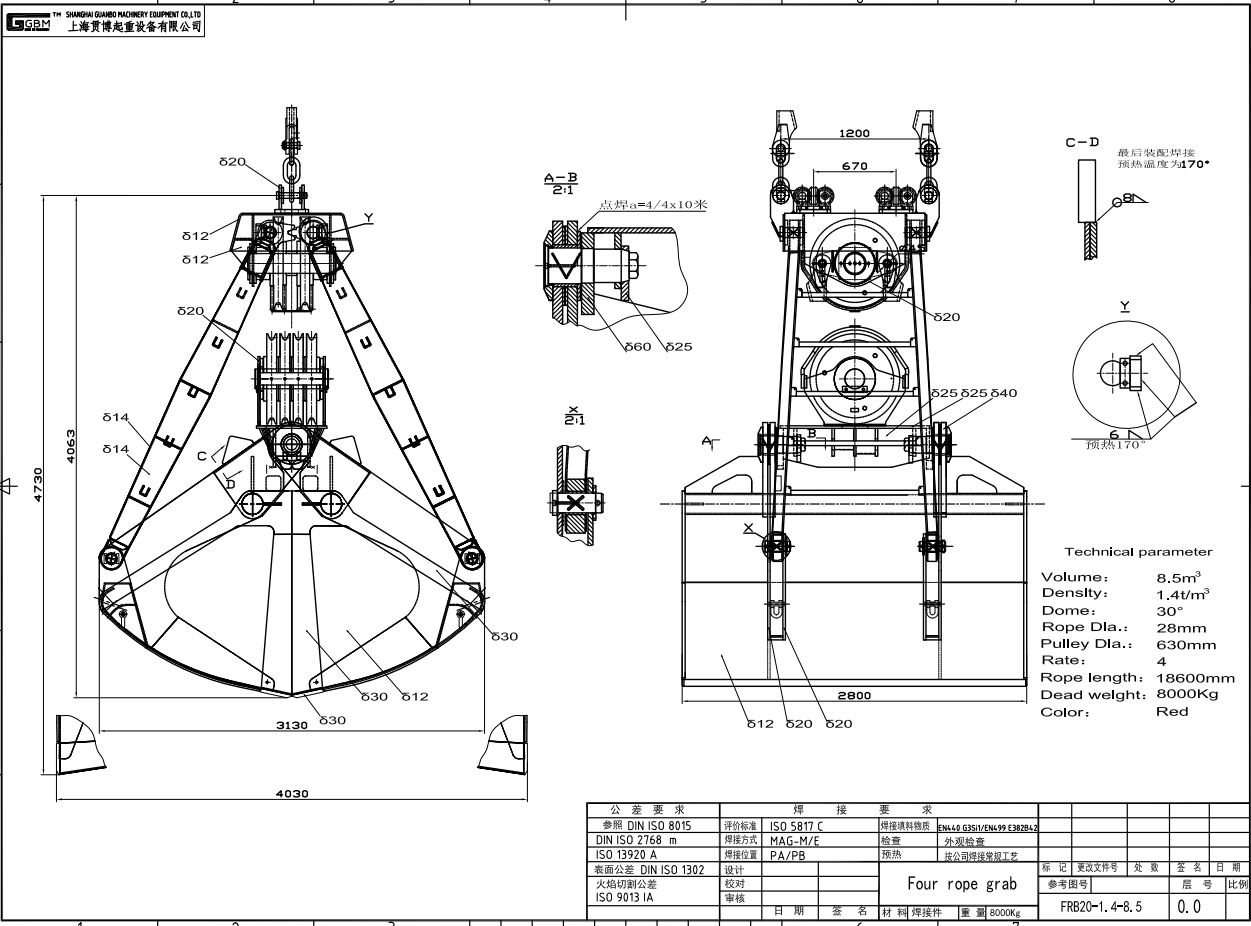

RFQ for rope grabs

Yes, every customer's working condition is different, all of our products can be customized depend on customers' requirements.

We could design leak proof, grab bucket with different capacity etc.

Normally shipping grabs in special containers FR,or bulk cargo vessel,which requires careful planning and preparation. Always make sure the hopper is secured so it doesn't slide around during transport.

GBM have it own experienced department for safe delivery,utilizing the services of a professional will ensure that the grab is securely in place and the container is ready to ship.

1.Where is the grab installed? Overhead cranes, gantry cranes or marine crane?

2. What is the main lifting material?

3. What is the grab volume required?

© Copyright - 2018-2021 : All Rights Reserved.

© Copyright - 2018-2021 : All Rights Reserved.