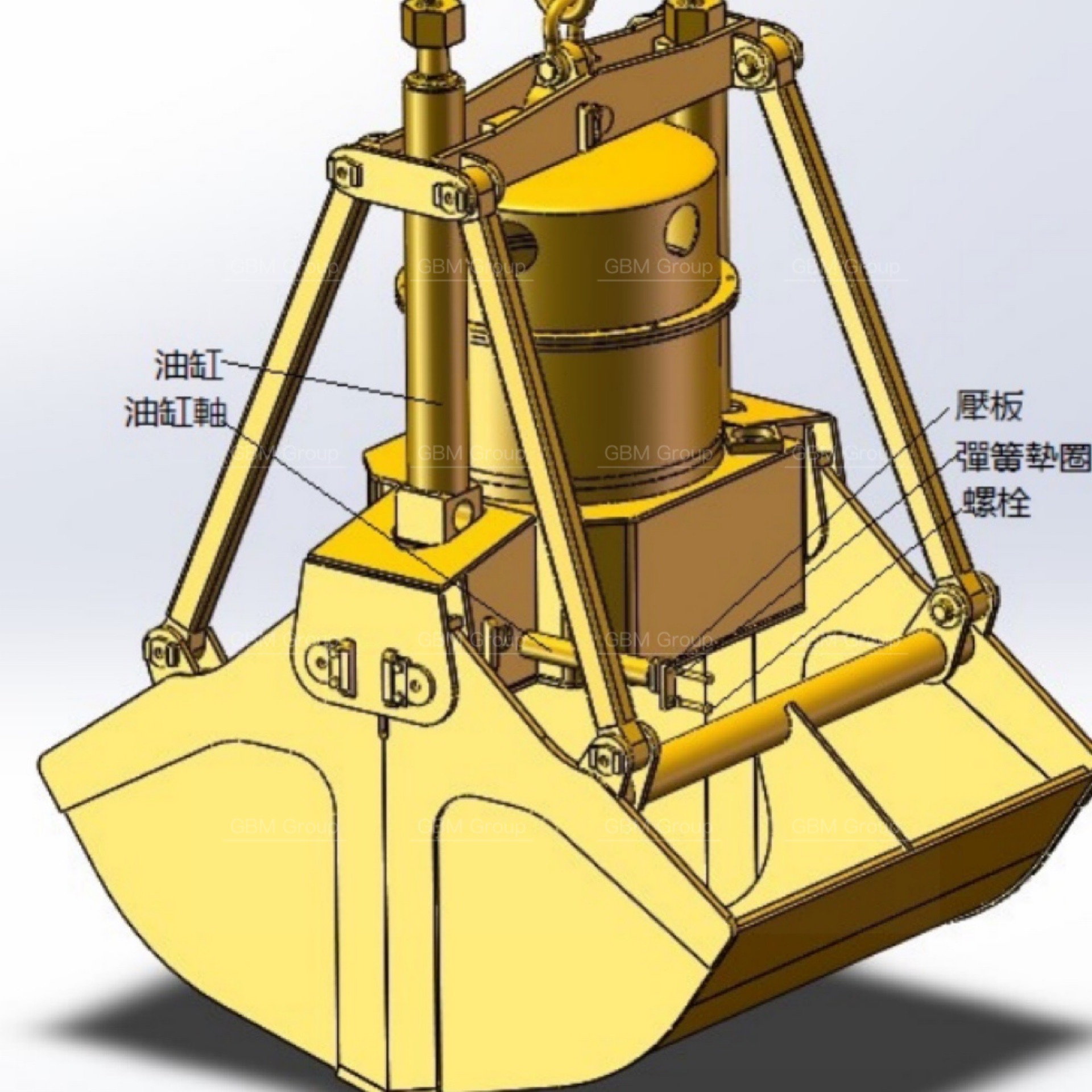

Electro-hydraulic clamshell grab

Advantage of hydraulic clamshell grab

Electro-hydraulic grabs have many features that set them apart from conventional grabs on the market. It integrates an advanced hydraulic system with an electro system for smooth and precise control of the gripping action. With its exceptional strength and durability, this grapple can handle heavy loads with ease, ensuring fast and efficient operations.

One of the most notable advantages of our electro-hydraulic clamshell grapples is their versatility. It has been specifically designed for a wide range of applications including but not limited to material handling in ports, construction sites and mining operations. The electro-hydraulic clamshell grapple simplifies maintenance with its rugged construction and high-quality materials. It is able to withstand harsh conditions, ensuring a longer service life and reducing the need for frequent repairs or replacements.

Why choose GBM as your grab supplier?

1.As a leading manufacturer of 5000 square feet dedicated, licensed and certificated staff.

2.Mechanical and machinery design, structural design and analysis dynamic modeling and seismic, failure modes and effects analysis Auto CAD, 3DMax, Math CAD, Solid Works, ANSYS and SAP2000 Advanced.

3.All Main parts using reliable original imported brand.

4.GBM provide the SGS, CCS, BV, CE, ABS, ISO9000:2008, ISO14001:2004, OHSAS and etc certifications, also accept third party inspection, such asSGS Factory test etc.

All the product design drawing and calculation is reasonable and meet the international standard, all the productions drawing and calculation will be audit before production.

5.The welding meet the international standards, and no damage detection reports are required.

6.On the testing the actual lifting capacity is 1.25 times than the rated lifting capacity and will issued exactly testing report according to the technical agreements

GBM grab experience in career

5 unit 12CBM hydraulic grab

Project located in UK

6 unit 12 CBM hydraulic grab

Project located in Jordan

1 unit 10 CBM hydraulic timber grab

Project located in Thailand

2 unit 20 CBM hydraulic grab

Project located in Mexico

1 unit 12 CBM hydraulic grab

Project located in Mexico

6 unit 12 CBM hydraulic grab

Project located in Chengxi shipyard

6 unit 12 CBM hydraulic grab

Project located in Panama

2 unit 15 CBM hydraulic grab

Project located in Greece

2 unit 2 CBM hydraulic grab

Project located in Taiwan

RFQ for hydraulic grabs

Yes, every customer's working condition is different, all of our products can be customized depend on customers' requirements.

We could design leak proof, grab bucket with different capacity etc.

Normally shipping grabs in special containers FR,or bulk cargo vessel,which requires careful planning and preparation. Always make sure the hopper is secured so it doesn't slide around during transport.

GBM have it own experienced department for safe delivery,utilizing the services of a professional will ensure that the grab is securely in place and the container is ready to ship.

1.Where is the grab installed? Overhead cranes, gantry cranes or marine crane?

2. What is the main lifting material?

3. What is the grab volume required?

4.Do you need cable drum?

© Copyright - 2018-2021 : All Rights Reserved.

© Copyright - 2018-2021 : All Rights Reserved.