Type of cranes we could produce

1、telescopic boom marine crane series

2、knuckle & telescopic boom marine crane series

3、knuckle boom marine crane series

4、stiff boom marine crane

5、E-crane

Considering safety features of Maritime Cranes,marine cranes are rquested following certifications:

a. (China Classification Society) CCS

b. (American Bureau of Shipping) ABS

c. (Bureau Veritas) BV

d. (Germanischer Lloyd) GL

e. (British Classification Society) LR

f. (Det Norske Veritas) DNV

g. (Rina Italiana) RINA

h (Russian Classification Society) RMRS

1.Designing

Our technicians will communicate to obtain your customization needs and Classification Society (IACS) certificates inquiry. After all requirements are finalized, our engineer team will design the crane Drawing.

2.Classification Society (IACS) Approved Drawing

After the sketch is completed, it will be reviewed by a third-party agency. GBM will select different classification societies for review according to the needs of customers. After the sketches are reviewed by the classification societies, we will start the formal processing process.

3.Classification Society (IACS) Material Inspection

We selected the corresponding classification society inspection according to the needs of customers. Related classification society will double check it. Strict review of materials can ensure the quality of products. Usually we use Q345B steel plate, if the product you buy is used in cold areas, we will use Q345D, Q345E type steel plate, which can support the use of sub-zero temperature. If you have special requirements, whether it is corrosion-resistant AH36 ship plate or stronger S690, HG70 ship plate, we can also customize according to your needs.

4.Raw Material Cutting

After that, we will do the blanking, cutting and forming of the material, these steps are all taken care of by our roughing team. We generally use Flame Cutting Machine, Plasma Cutting Machine and Laser Cutting Machine, and we will choose the appropriate cutting method according to the needs.

5.Welding

Our welding process can reach welding procedure specification, such as WPS standard. Our welders are qualified by CCS,ABS and AWS. After welding,We will carefully polish the dents and welds to ensure the product is flat and beautiful.

6.Welding defect inspect

Third-party organizations perform non-destructive testing, such as radiographic or ultrasonic testing, to ensure product quality is absolutely safe and reliable. We use Ultrasonic detection to inspect the external defects, Internal defects or non-destructive test for weld joint.

7.Sandblasting

When sandblasting (SA2.5) is completed, We will start the painting steps. Some marine cranes manufacturers will skip this step to reduce cost.However, the primer can easily peel off under natural conditions if skip sandblasting.In addition, our primer adopts high-quality epoxy zinc rich primer.We also use Jotun C5 Marine Standrad Topcoat. It dries quickly, has strong adhesion and strong anti-corrosion ability.

8.components certification

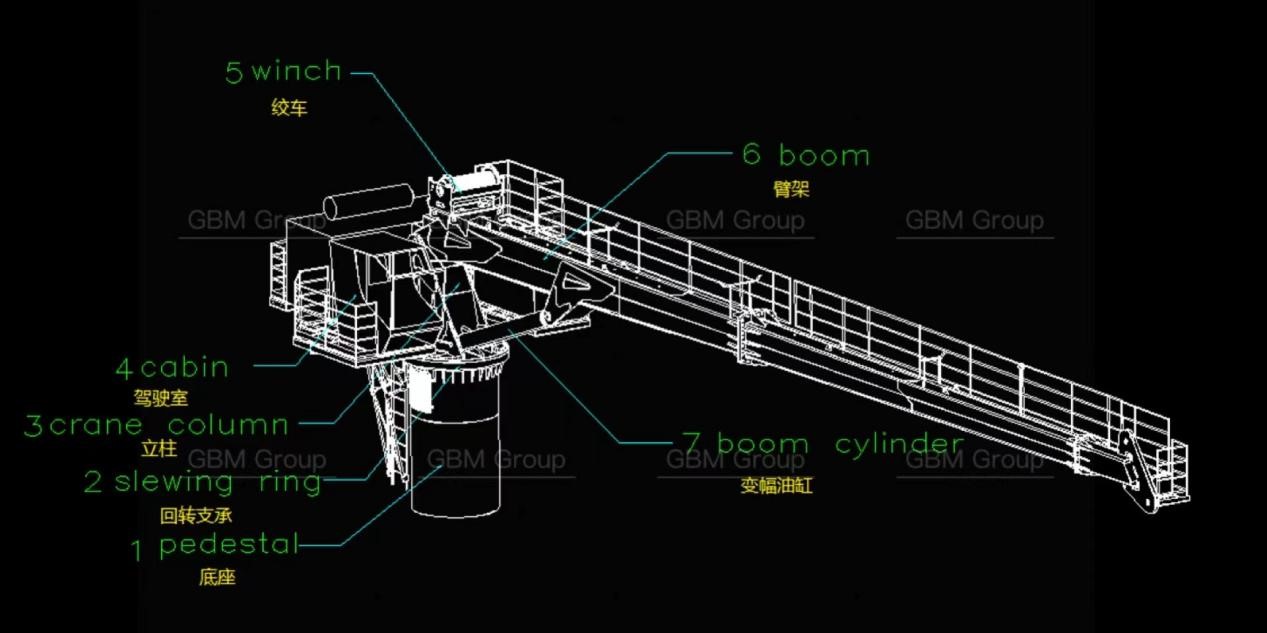

The components of the crane: (cylinder) base, slewing bearing, operating platform (cab), column (tower), winch, rotary reducer, boom, luffing cylinder, wire rope, pulley block, hook, shackle , electrical system (electric control box), hydraulic system and other components, all steel plate materials must be certified by the classification society.

9.Simulate Marine Test

After pedestal installation and boom installation,debugging on a special platform which can simulate marine environment is necessary.We will test the range of heel and trim in the working state of the crane to check whether it is qualified.

10.Classification society acceptance procedure

Classification society Inspectors and our staff will do the load tests on a special platform which can simulate marine environment outdoors.We will check the accuracy of the safe working load of the marine crane.

11.packaging and transport

Our packaging team takes care of the packing and delivery of the products. When the products arrive at your designated location, the crane is ready to be installed on your ship or other platform, and our installation team will provide you with installation guidance in various ways if needed.

Post time: May-11-2022

© Copyright - 2018-2021 : All Rights Reserved.

© Copyright - 2018-2021 : All Rights Reserved.