Bagging machine

Bagging machine

With the success of the first generation of mobile bagging machines, gbm has since diversified into other sectors of the maritime industry including terminal management, warehousing and consultancy. As a result, GBM has broadened its equipment catalogue to include bulk hoppers, grabs and other bespoke bagging equipment.

Supporting the technicians in the field, providing around the clock assistance, after-sales support, technical trouble shooting and front-line support for commercial enquiries, now boasts some of the most robust levels of customer service in the cargo handling equipment market.

GBM Mobile Containerized Bagging Machine Development

The world's first mobile bagging machine designed specifically to be housed within two ISO standard shipping containers, revolutionising the bulk commodity handling industry, allowing commodities to be shipped in bulk and bagged at destination, yielding previously unheard-of savings in the movement of commodities in bulk across the globe.

As a pioneer in its field, GBM is now able to call upon over 15 years of real world operational experience to refine the technology in its bagging machines and has since patented a wide range of cargo handling equipment with unrivalled features, operational flexibility and build quality, which now serve an international clientele in over 30 countries.

Main Application of port Bagging machine

GBM's range of bagging machines are specifically designed to cater for bagging operations such as:

1.Quayside for direct discharge from vessel

2.Port warehouse operations

3.Inland storage and distribution depots

4.Blending plant facilities

5.Commodity storage silos

GBM eco-hopper experience in career

100T/H Two line bagging machine

Project located in Bengal

2 unit 100T/H Two line bagging machine

Project located in Philippines

4 unit 100T/H Two line bagging machine

Project located in Tanzania

4 unit 100T/H Two line bagging machine

Project located in Saudi Arabia

8 unit 100T/H Two line bagging machine

Project located in Taiwan

4 unit 100T/H Two line bagging machine

Project located in Djibouti

RFQ for port container bagging machine unit?

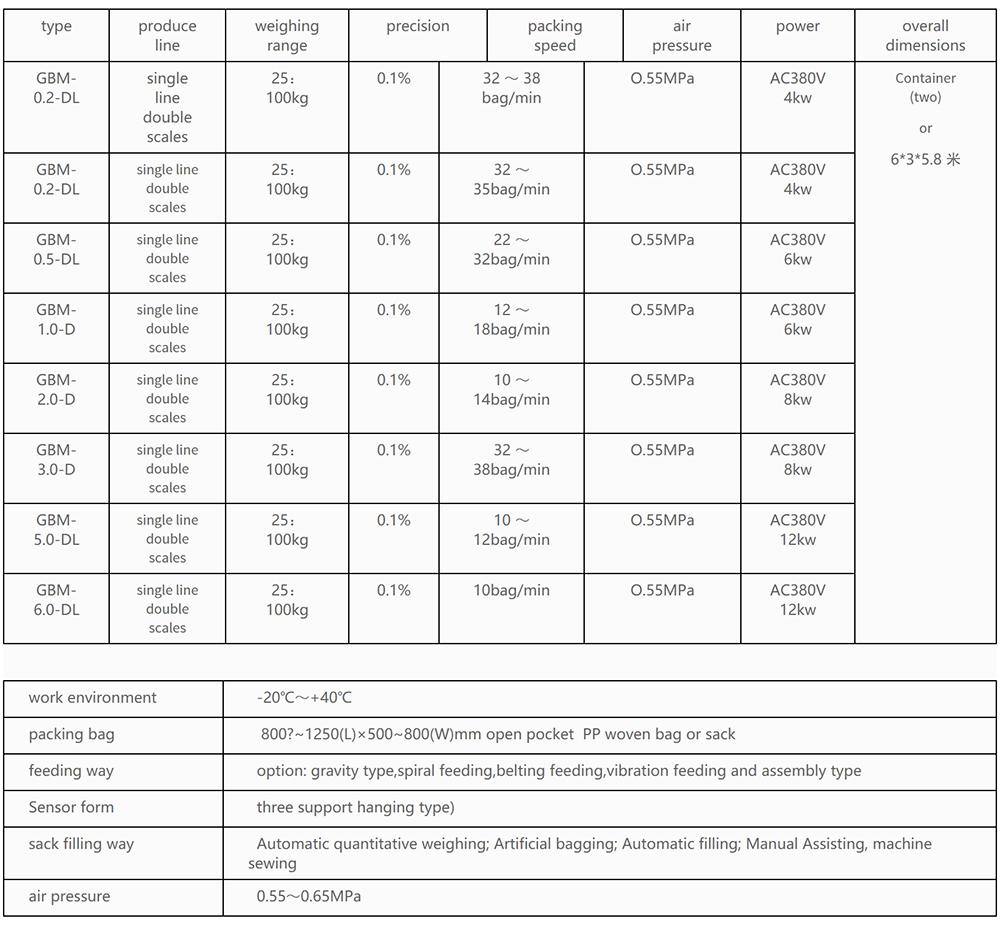

Yes, every customer's working condition is different, all of our products can be customized depend on customers' requirements. Please see the below hopper type we could produce for you:

Two packing line bagging machine with cyclone dust-control system

One packing line bagging machine Fixed stationary Eco hopper

Two container bagging machine

One container bagging machine

Rail type container bagging machine

Normally shipping goods in containers or bulk cargo vessel,shipping in containers requires careful planning and preparation. Always make sure the hopper is secured so it doesn't slide around during transport.

GBM have it own experienced department for safe delivery,utilizing the services of a professional will ensure that the bagging machine is securely in place and the container is ready to ship.

1. What is material will pack by bagging machine?

2. What is the packing efficiency per day?

3. Does it unload by grab and how about grab dimension?

1) The general layout of the hopper(including the main dimensions and performance parameters) and the structure specification.

2) Layout drawing, assembly drawing and processing drawing of wearing parts of each mechanism of the hopper

3) Electrical equipment system diagram, layout diagram, wiring diagram, and control principle diagram.

4) Cable, conduit or trunking layout.

5) The schematic diagram of the hydraulic system and its description.

6) Product structure diagram of purchased parts, instruction manual and maintenance manual.

© Copyright - 2018-2021 : All Rights Reserved.

© Copyright - 2018-2021 : All Rights Reserved.